"Uh, Kyle? I think we broke the DC motor."

I looked at Christopher, grimacing hard. He handed the hefty thirty dollar potential paperweight to me, and I gripped the attachment at the end of the shaft. It spun easily. Too easily. If this component bricked, the project was dead in the water. Dead.

Almost three weeks earlier, on March 25th, Ms. Jayakar's eighth-grade science class sat down as she announced the first project of the year. (Funny, because the year was about to end.) The prompt: "To create something useful that demonstrated a California science standard."

That was it, and the class started gathering into groups of four. That's how the team started—me, Christopher, Nikhil, and Shaurya. We were all already friends, and each of us had decent knowledge in some form of science, so I expected the project to turn out decently.

Brainstorming commenced. We tossed out a few ideas to each other:

- A gyroscopic cupholder that would prevent drinks from spilling. (Rejected. It looked like we'd need 3D printing for this, and none of us had a printer.)

- A rocket that used chemical reactions to propel itself high up. (Rejected. We probably wouldn't even be allowed to take that to school, let alone demonstrate it.)

- An electricity generator, using arm-generated torque to create voltage.

And that was the seed of the idea for the project—a dynamo. It'd spin a neodymium magnet inside a coil of copper wire, and there'd be a current coming out of that wire. Usable electricity. Everyone agreed that it was a cool idea, and we started researching Faraday's Law of Electromagnetic Induction to figure out what kind of magnet and what kind of solenoid (a coil of wire that forms a magnetic field) we'd need for this project.

When I came home that day, I started looking around. The index card we had to turn in needed a team name, and none of us had decided on one. I admired the branding and UI aesthetic of the Arc Browser, a recently released web browser made by a startup in New York. So as to not blatantly copy, I decided to go with the "circle geometry" theme and named it Chord.

The next day, I wrote the team name onto the card and everyone went with it. When Ms. Jayakar asked why it was named "Chord," I didn't want to say "because it sounded good", so I improvised an explanation—"It's named Chord, as in music. Because, uh, this device generates electricity to play music."

Ms. Jayakar just nodded and walked away. The whole team looked at me.

"So," Shaurya said. "New feature, huh?"

March 31st

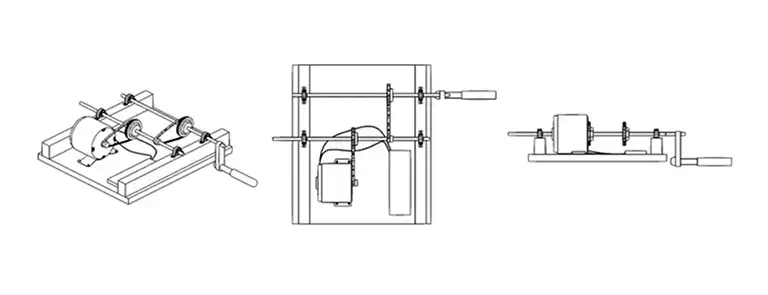

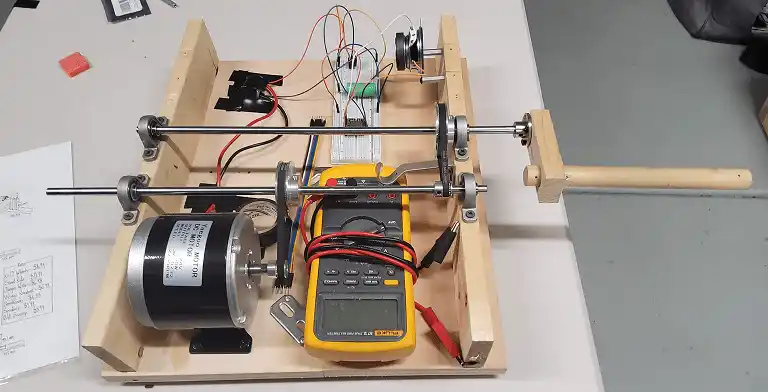

At the end of March, I drafted a design that'd use a gear ratio to spin a magnet inside a solenoid in Blender. It worked with a crank attached to a drive shaft, and a gear ratio would spin the driven shaft at an increased RPM. The driven shaft held the neodymium magnet, and it'd spin inside the solenoid to produce voltage. The box would contain the electronics, and the truncated Hershey's Kiss shape was supposed to be a speaker.

April 3rd

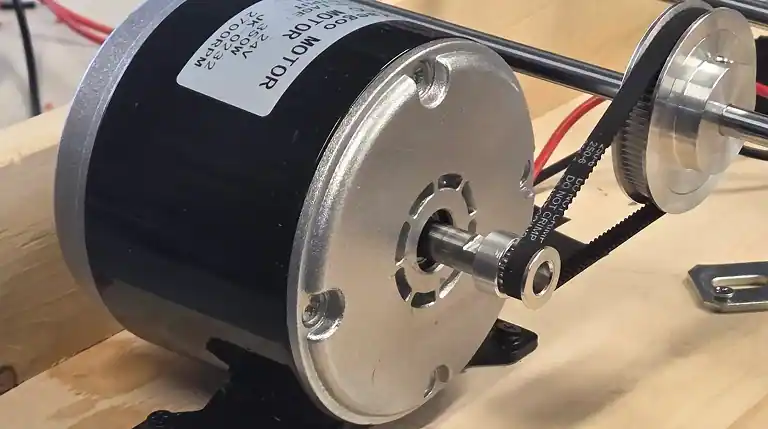

At 2:26, about an hour after school (Thursdays were short days), the whole group hopped onto a call to discuss how we'd actually build this. As I fried sea bass in a pan, we decided to replace the solenoid/magnet combo with a DC motor. I reasoned that it'd just be more feasible to build with, and soon enough, the rest of the group agreed with me.

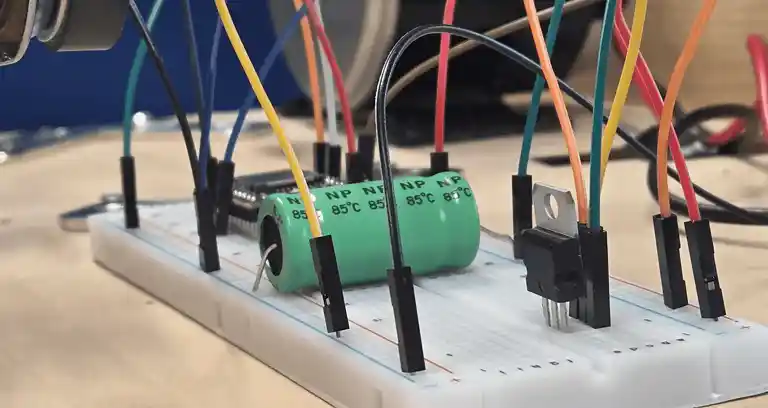

The electronics to convert raw energy into music was actually simple enough. All we needed was a breadboard to attach everything to, a capacitor, a voltage regulator, an MP3 player, and of course, a speaker. This is the list we settled on:

- YaeTek 24V DC Motor

- Befenybay Synchronous Wheels

- Eowpower Pillow Bearings

- Metal Rods

- Breadboards

- Jumper Wires

- L7805CV 5V Regulator

- 100μF 100V Capacitor

- DFPlayer Mini

- 4 Ohm 3 Watt Speakers

The total? $129 USD. That was way more than any of us had ever spent on a science project before and this meant that the project had to succeed. Each of us was pouring over $30 into this.

April 6th

First day of construction began. After finalizing some designs in Blender (distinctly remember My Little Pony S1E8 in the background during this), I had the blueprints.

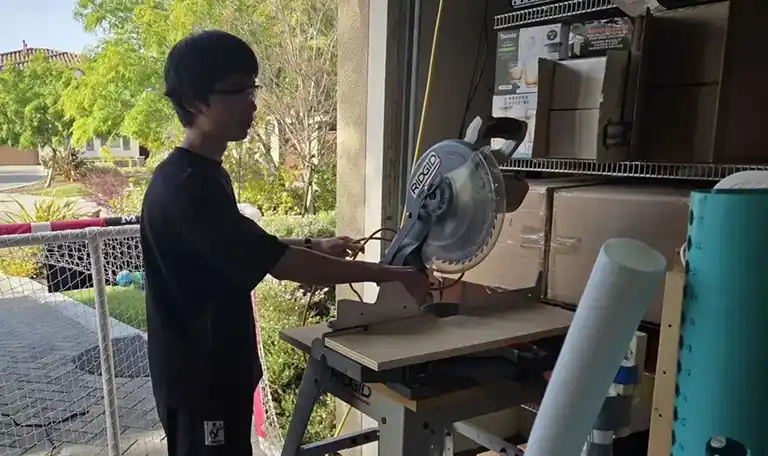

That day, me, Christopher, and Nikhil cut wood like we'd never cut wood before. The base was measured and cut with a miter saw. The planks that elevated the pillow blocks and axles were drilled onto the base. (It was Nikhil's first time using a drill.)

And that's when the problem happened. See, the shaft of the DC motor had a nut and a starburst shaped metal attachment. We needed to connect the shaft to one of the small synchronous wheels, so intuitively, we used pliers and started twisting the nut. It didn't budge.

Since it didn't move, we concluded that the manufacturers must've meant for us to unscrew those four screws on the face of the motor. So while I worked on securing the pillow bearings and the shafts, Nikhil and Christopher tinkered with the motor. They lifted the face, and something fell loose.

"Uh, Kyle? I think we broke the DC motor."

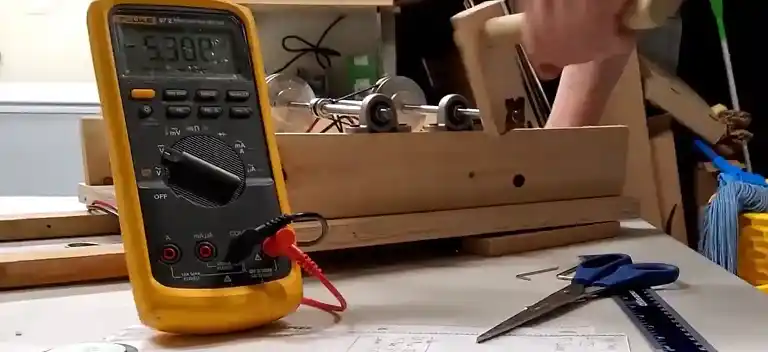

And sure enough, it seemed broken. Spinning the shaft, I felt no resistance, and using the multimeter confirmed that we weren't generating voltage effectively. At that point, it was 6:30 in the evening. We messed around a bit more, had some fun with Christopher's barbell, attempted handstands, and then it came time to go. The wood part of the project was finished, and all the mechanical components were attached. As we waved goodbye, I nervously hoped that he'd find a fix.

April 7th

Fixed. Christopher and his dad worked on the motor, and it's back to generating voltage effectively. Still not sure exactly how we broke it, but they found a solution. And the shaft of the motor? It turns out that we were actually supposed to remove the nut. We weren't strong enough, so we concluded that it must have not been the intended method. Christopher's dad, however, removed it easily and we were finally able to attach the synchronous wheel.

The fix worked. The crank and gear ratio spun that shaft at a high RPM, and we were getting consistently over 5 volts of output.

April 8th

In the middle of 4th period US History, I have trouble keeping my head up. I feel hot and I can't pay attention. After excusing myself to the nurse's office, I lay in one of their beds. Once my mom arrives in her car, my head's already pounding from the fever. I can barely talk. Turns out that I've got influenza, along with half the school.

April 9th

Our team decides on the song that'll be put in the DF Player Mini—Taylor Swift's Bad Blood. I chose this song because it was a Taylor Swift song and would probably be the best choice for presenting this project. (No profanity, mainstream music, inconspicuous)

My fever starts fading and I realize that I need to start locking in for the electronics portion of the project. Christopher helped us get to a stage where the motor could produce electricity. I needed to turn that into music. After watching a few videos, I had a good idea of how a breadboard worked: power rails on the sides move electricity vertically and the rows move it horizontally.

April 13th

At 5:30 on this day, Nikhil's dad picks me up in his Tesla. I'm wearing a mask and slightly suffering because I can't breathe very well, but I'm excited for this day. Nikhil and I chat a bit during the ride, and then we arrive at Christopher's garage.

First, we cut off the spade terminals on the end of the DC motor wires and strip it to expose a bit of raw wire. Christopher's dad showed us his wire splicing connectors, which we used to connect the DC motor to jumper cables.

The positive jumper went to the positive rail on the right, and the negative jumper went to the negative rail on the left. Next, jumper cables downstream on the rail connected to the appropriate pins on the voltage regulator. The output from that signal went to the capacitor and powered the DF Player Mini. The DF Player Mini was then wired to the speaker, which produced the final output sound.

That night, when we left, the project worked. We successfully produced a Taylor Swift song on a speaker powered only by spinning a crank.

Reflection

This was a great introduction to electronics for me, and definitely was a highlight of my 8th grade experience. I wonder if it might've worked with the electromagnetic induction approach, and perhaps I'll even get to test out a similar mechanic in the future.

During high school, I'm planning to build a personal mobility vehicle called the Chord Lightning, which is supposed to have a welded AISI 1080 steel frame and move with differential skid steering controlled by joysticks. If I ever get an opportunity to do this, I'll definitely be calling on this team.

That's everything. Thanks for reading, and until next time, I am out.